The latest Welder Generators from leading brands

ISO 9001 Registered Company

Automation Robotics Line

Cebora has created a line of power sources purposely designed and developed for applications in the automation and robotics field.

The wide present range includes power sources for pulsed MIG welding, TIG welding and plasma welding that can be used joined to the various types of robots.

The Cebora power sources of the Automation line are used together with robots and pantographs of the best makes all over the world.

MIG Robot

Evo Speed Star 380 TS Robot (Art.319.80)

The Cebora range for MIG/MAG applications in the sector of robotics and automation consists of two three-phase inverter based power sources EVO Speed Star of 380A (art. 319.80), with optional cooling unit GRV12 and 500A (art. 320.80), already fitted with cooling unit.

These power sources can work with programs that can be recalled by the robots (job) in synergic, pulsed (optional function) and double pulsed (optional function) mode.

In addition to the control panel and to the wire feed unit in aluminium, the power sources can be equipped with different type of interface (analogic and digital), spool holders and liners, connections and wirings of different lengths according to the specific needs of each user.

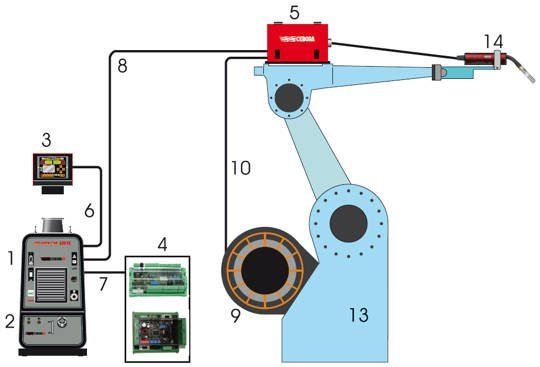

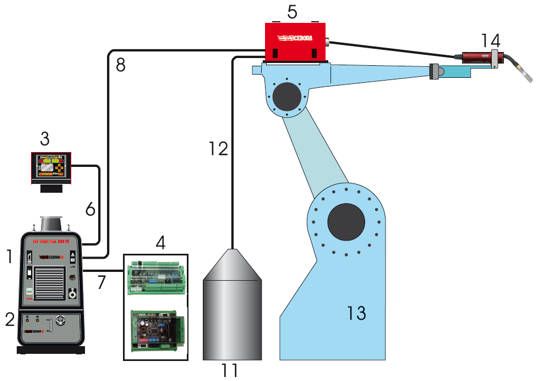

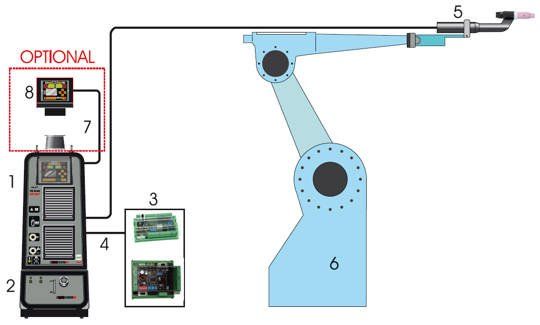

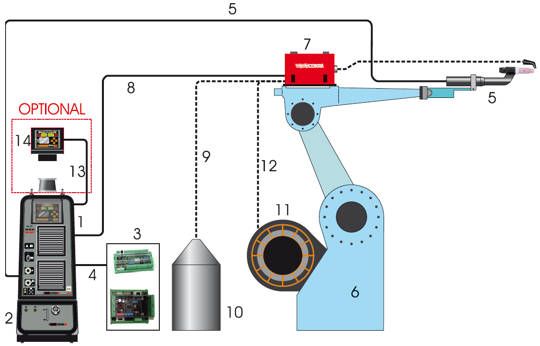

Connections Diagram:

1) With spool holder

2) With "Marathon Pack"

Legend:

- Power source

- Cooling unit

- Control panel

- Interface

- Wire feed unit

- Connection power source / control panel

- Connection power source / robot

- Connection power source / wire feed unit

- Spool holder for robot

- Liner spool holder / wire feed unit

- Marathon pack

- Liner Marathon Pack / wire feed unit

- Robot

- Torch

Evo Speed Star 520 TS Robot (Art. 320.80)

The Cebora range for MIG/MAG applications in the sector of robotics and automation consists of two three-phase inverter based power sources EVO Speed Star of 380A (art. 319.80), with optional cooling unit GRV12 and 500A (art. 320.80), already fitted with cooling unit.

These power sources can work with programs that can be recalled by the robots (job) in synergic, pulsed (optional function) and double pulsed (optional function) mode.

In addition to the control panel and to the wire feed unit in aluminium, the power sources can be equipped with different type of interface (analogic and digital), spool holders and liners, connections and wirings of different lengths according to the specific needs of each user.

Connections Diagram as above.

TIG Robot DC

TIG DC Evo 320/t Robot (Art. 373.80)

Cebora offers, for TIG welding applications in the field of automation and robotics, two DC TIG welding power sources of 320 and 500A and three AC-DC TIG welding power sources from 260 to 450A. The 500 DC model (Art 363.80) and the AC-DC models 450A (Art.371.80) and 330A (Art.370.80) are complete with cooling unit, while for the 320A DC model (art. 373.80) and 260A AC-DC model (Art. 369.80) the cooling unit is optional.

The power sources are suitable for welding also in the “cold wire” configuration (that is with filler material in continuous wire), using the various purposely developed accessories.

It is also possible to equip the power sources with an analogic type interface, with its relevant wirings and connections of different lengths.

The “cold wire” version, which requires to fit in the power source the optional wire feed unit power supply kit art. 111, also includes a dedicated wire feed unit WF4-R6 (art. 1667), spool holders and liners, connections and wirings of different lengths according to the specific needs of each user.

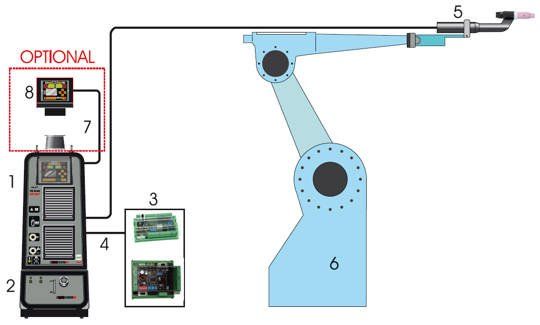

CONNECTIONS DIAGRAMS as above

TIG DC Evo 500/T Robot (Art. 363.80)

Cebora offers, for TIG welding applications in the field of automation and robotics, two DC TIG welding power sources of 320 and 500A and three AC-DC TIG welding power sources from 260 to 450A. The 500 DC model (Art 363.80) and the AC-DC models 450A (Art.371.80) and 330A (Art.370.80) are complete with cooling unit, while for the 320A DC model (art. 373.80) and 260A AC-DC model (Art. 369.80) the cooling unit is optional.

The power sources are suitable for welding also in the “cold wire” configuration (that is with filler material in continuous wire), using the various purposely developed accessories.

It is also possible to equip the power sources with an analogic type interface, with its relevant wirings and connections of different lengths.

The “cold wire” version, which requires to fit in the power source the optional wire feed unit power supply kit art. 111, also includes a dedicated wire feed unit WF4-R6 (art. 1667), spool holders and liners, connections and wirings of different lengths according to the specific needs of each user.

CONNECTIONS DIAGRAM - basic config

Legend:

- Power source

- Cooling unit

- Interface

- Connection power source / robot

- Torch

- Robot

- Connection power source / remoted control panel

- Remoted control panel

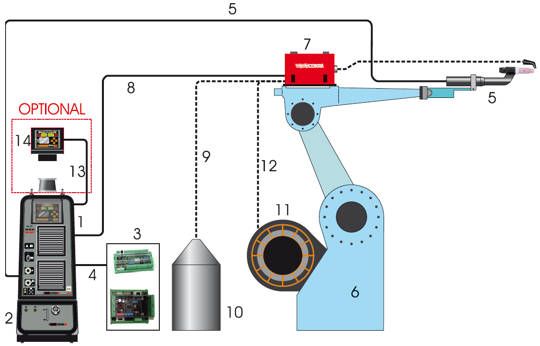

CONNECTIONS DIAGRAM - config with cold wire

Legend:

- Power source

- Cooling unit

- Interface

- Connection power source/ robot

- Torch

- Robot

- Wire feed unit

- Connection power source / wire feed unit

- Liner Marathon Pack / wire feed unit

- Marathon Pack

- Spool holder for robot

- Liner spool holder / wire feed unit

- Connection power source / remoted control panel

- Remoted control panel

TIG Robot AC/DC

TIG AC-DC EVO 260/T Robot (Art.369.80)

Cebora offers, for TIG welding applications in the field of automation and robotics, two DC TIG welding power sources of 320 and 500A and three AC-DC TIG welding power sources from 260 to 450A. The 500 DC model (Art 363.80) and the AC-DC models 450A (Art.371.80) and 330A (Art.370.80) are complete with cooling unit, while for the 320A DC model (art. 373.80) and 260A AC-DC model (Art. 369.80) the cooling unit is optional.

The power sources are suitable for welding also in the “cold wire” configuration (that is with filler material in continuous wire), using the various purposely developed accessories.

It is also possible to equip the power sources with an analogic type interface, with its relevant wirings and connections of different lengths.

The “cold wire” version, which requires to fit in the power source the optional wire feed unit power supply kit art. 111, also includes a dedicated wire feed unit WF4-R6 (art. 1667), spool holders and liners, connections and wirings of different lengths according to the specific needs of each user.

CONNECTIONS DIAGRAM (basic configuration)

Legend:

- Power source

- Cooling unit

- Interface

- Connection power source / robot

- Torch

- Robot

- Connection power source / remoted control panel

- Remoted control panel

CONNECTIONS DIAGRAM - config with cold wire

Legend:

- Power source

- Cooling unit

- Interface

- Connection power source/ robot

- Torch

- Robot

- Wire feed unit

- Connection power source / wire feed unit

- Liner Marathon Pack / wire feed unit

- Marathon Pack

- Spool holder for robot

- Liner spool holder / wire feed unit

- Connection power source / remoted control panel

- Remoted control panel

TIG AC-DC Evo 330/T Robot (Art. 370.80)

Cebora offers, for TIG welding applications in the field of automation and robotics, two DC TIG welding power sources of 320 and 500A and three AC-DC TIG welding power sources from 260 to 450A. The 500 DC model (Art 363.80) and the AC-DC models 450A (Art.371.80) and 330A (Art.370.80) are complete with cooling unit, while for the 320A DC model (art. 373.80) and 260A AC-DC model (Art. 369.80) the cooling unit is optional.

The power sources are suitable for welding also in the “cold wire” configuration (that is with filler material in continuous wire), using the various purposely developed accessories.

It is also possible to equip the power sources with an analogic type interface, with its relevant wirings and connections of different lengths.

The “cold wire” version, which requires to fit in the power source the optional wire feed unit power supply kit art. 111, also includes a dedicated wire feed unit WF4-R6 (art. 1667), spool holders and liners, connections and wirings of different lengths according to the specific needs of each user.

TIG AC-DC Evo 450/T Robot (Art. 371.80)

Cebora offers, for TIG welding applications in the field of automation and robotics, two DC TIG welding power sources of 320 and 500A and three AC-DC TIG welding power sources from 260 to 450A. The 500 DC model (Art 363.80) and the AC-DC models 450A (Art.371.80) and 330A (Art.370.80) are complete with cooling unit, while for the 320A DC model (art. 373.80) and 260A AC-DC model (Art. 369.80) the cooling unit is optional.

The power sources are suitable for welding also in the “cold wire” configuration (that is with filler material in continuous wire), using the various purposely developed accessories.

It is also possible to equip the power sources with an analogic type interface, with its relevant wirings and connections of different lengths.

The “cold wire” version, which requires to fit in the power source the optional wire feed unit power supply kit art. 111, also includes a dedicated wire feed unit WF4-R6 (art. 1667), spool holders and liners, connections and wiring's of different lengths according to the specific needs of each user.

Plasma Welding DC - AC-DC Robot (Art. 465)

Cebora offers, for Plasma Welding applications in the field of automation and robotics, two DC TIG welding power source of 320 and 500A and three AC-DC TIG welding power sources from 260 to 450A. The 500 DC model (Art 363.80) and the AC-DC models 450A (Art.371.80) and 330A (Art.370.80) are complete with cooling unit, while for the 320A DC model (art. 373.80) and 260A AC-DC model (Art. 369.80) the cooling unit is optional.

The power sources are suitable for welding also in the “cold wire” configuration (that is with filler material in continuous wire), using the various purposely developed accessories.

All power sources are factory fitted with an integrated CANopen digital robot interface.

Should it be necessary to install a different external robot interface, either digital (Profibus, art. 107.01, or DeviceNet, art. 107.02) or analogic (art. 217.01), this must be purchased separately.

The “cold wire” version, which requires to fit in the power source the optional wire feed unit power supply kit art. 111, also includes a dedicated wire feed unit WF4-R6 (art. 1667), spool holders and liners, connections and wirings of different lengths according to the specific needs of each user.

INDEPENDENT WELDING SERVICES LTD LATEST NEWS

NEWS

TWITTER

FACEBOOK

01179 352 540 | info@indeweld.com

© 2024

All Rights Reserved | Indeweld

WE ACCEPT THE FOLLOWING PAYMENTS: